Project Solutions

Cattle, sheep, and camels are ruminants, so cattle feed belongs to ruminant feed, and cattle feed is divided into concentrated feed and complete mixed feed.

Raw materials for cattle feed processing: corn, wheat, barley, soy meal, molasses, etc. there are also formulas containing thick fiber raw materials such as grass, hay, straw, alfalfa.

Cattle pellet feed size: 4-10mm.

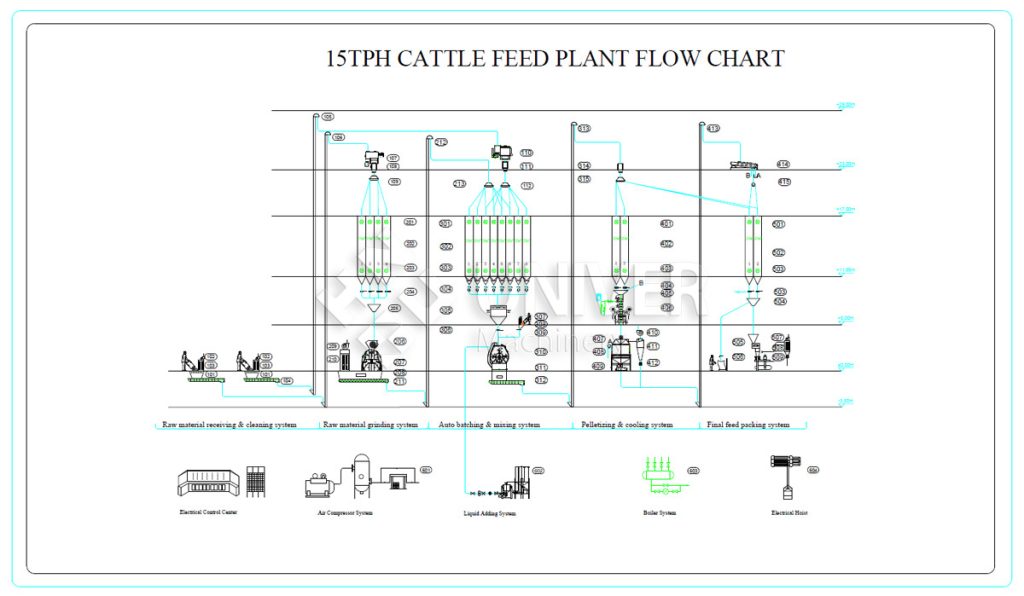

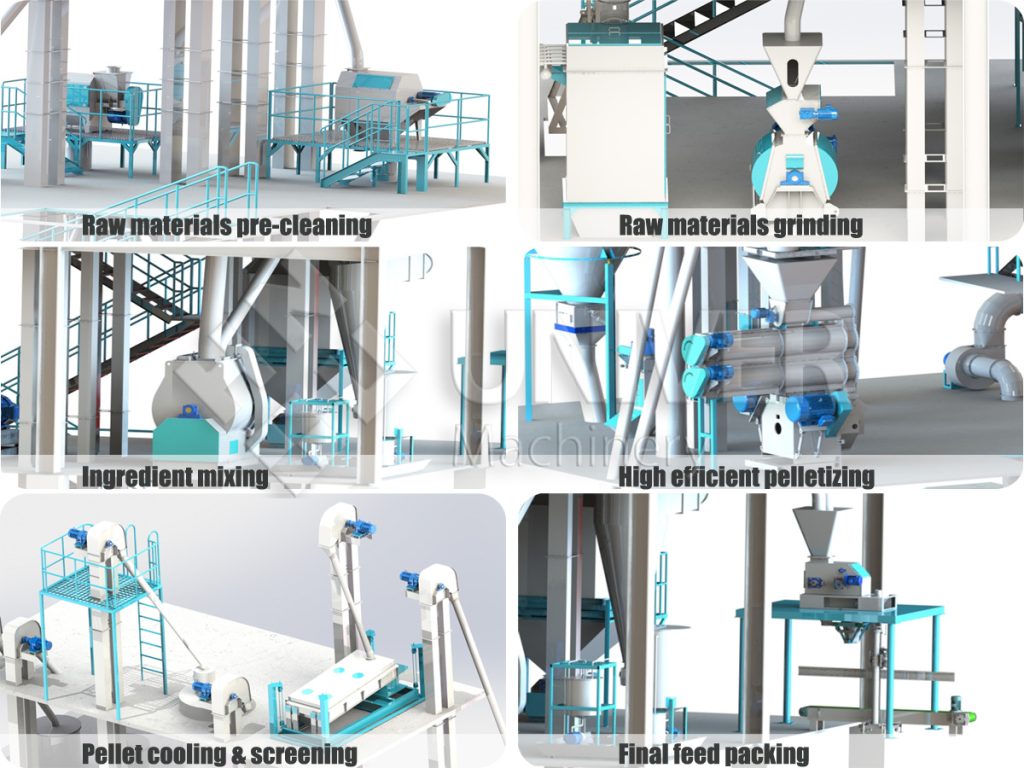

Raw material receiving & cleaning section: grain materials and powder materials are fed separately and cleaned separately.

Grinding section: total 4 pre-grinding bins, hammer mill capacity: 10-15tph.

Auto-batching and mixing section: 8 proportioning bins, the batching program controls the batching scale to achieve precise batching. Liquid adding equipment includes oil adding machine, molasses adding machine, etc. to add oil and molasses to mixer machine.

Pelletizing & cooling section: 2 pre-pelletizing bins, with crumbler machine for crumbled pellet processing.

Packing section: automatic packaging and sewing in bags.

Please leave your brief information as below, we will get back to you as soon as possible.

Leave your needs, we will get in touch with you as soon as possible!