Project Solutions

Raw materials for wood pellet processing: korean pine, white pine, fir, oak, birch, elm, aspen wood, cedar, bean stalk, cotton stalk, peanut shell, cornstalk, rape stem, wheat straw, potato straw, rice straw, wood, sawdust, wood chips, bamboo dust, palm wire, etc.

Raw material moisture: 13-18%;

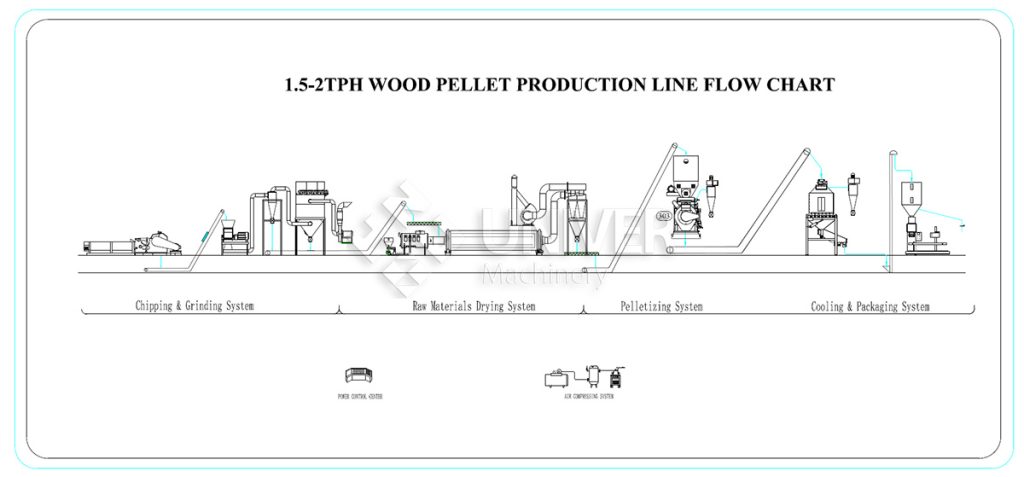

Process section: wood chipping ---grinding---drying---pelletizing & cooling ---screening & packing.

Design capacity: 1.5-2tph;

Wood pellet size: 6-10mm;

Total power consumption: 315.3kw;

1. Process can be customized according to customer’s requirements.

---When the moisture content of the raw materials is higher than 20%, it is necessary to add drying equipment and use a dryer to dry it to 13-18% before pelletizing.

---Final feed can be packed in bags, or in bulk silo.

2. The complete line has a compact design, and meets environmental protection requirements.

Please leave your brief information as below, we will get back to you as soon as possible.

Leave your needs, we will get in touch with you as soon as possible!