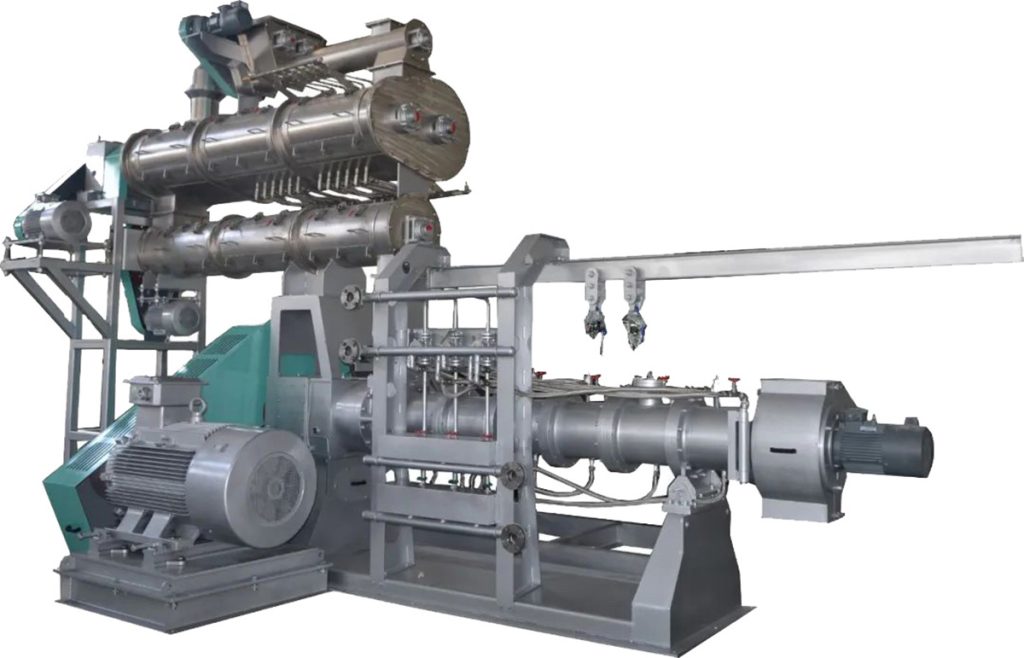

I. Working principle of feed extruder

The feed extruder converts feed with high water content into a physical reaction of high temperature and high pressure, so that the feed can meet the animal's nutritional needs and improve the utilization rate of the feed. The main principles are mainly the following three steps:

1. Increased pressure

The feed extruder sends the feed with high water content into the expansion chamber, and then passes through the screw propeller to subject it to high pressure. In the expansion chamber, the water content of the feed gradually evaporates, the volume gradually expands, and the pressure increases. When it reaches a certain value, the feed is squeezed into the die hole.

2. Puffing process

When the feed passes through the mold hole, it faces extremely high temperatures and pressures. Under such high temperature and high pressure environment, the moisture and oil inside the feed expand rapidly, and the feed undergoes violent physical reactions. Through such a reaction, nutrients such as starch and protein in the feed are released and fully mixed to form a more digestible state.

3. Pressure reduction and cooling

After the expansion process, the feed enters the decompression chamber, where the pressure is rapidly reduced and cooled by the sprayer, making the feed volume smaller and the shape more stable, while part of the water evaporates again.

II. Extrusion process of feed extruder

The expansion process of the feed extruder refers to the rapid expansion of the feed through high temperature and high pressure, and the release of useful nutrients inside it. Specifically, it includes the following steps:

1. Feed is added to the expansion chamber and pressurized by a screw propeller;

2. The pressure gradually increases, the steam is gradually released, and the feed volume is gradually expanded.

3. The feed enters the mold hole. Under the action of high temperature and high pressure, the water and grease inside the feed expand rapidly, resulting in a violent physical reaction;

4. During the process, nutrients such as starch and protein in the feed are released, forming a state that is easier to digest;

5. After puffing, the feed enters the decompression chamber, the pressure is reduced, and part of the water is released again. At the same time, through the cooler, the feed volume becomes smaller and the form becomes more stable.

III. Application scope of feed extruder

The feed extruder is suitable for processing various feeds, especially for the processing of raw materials such as pellet feed, thick feed, household garbage, rice straw, and sawdust. The expanded feed has the advantages of being loose, easy to digest, and good in taste, so it is widely used.

In short, the working principle of the feed extruder is mainly to cause physical changes in the feed through high temperature and high pressure to release nutrients and thereby improve feed utilization. Feed extruder has a wide range of applications and is an important equipment in modern feed processing.