- Application: feed industry 6*1000T corn silo & 12*200T soya mill silo;

- Project location: China.

- Storage material: corn, soya meal.

- Incoming material form: bulk truck incoming material and discharging automatically.

- Assembled steel silo: made of high quality 275g/㎡ galvanized steel.

- Cone bottom: steel structure supporting steel silo

- Auxiliary system: ventilation system, temperature measurement system, material level system, pre-cleaning system according to customer’s requirement.

Details of this silo project:

- 1. The discharging section is a hydraulic back-turning unloading, and the unloading grid screen is a non-load-bearing model.

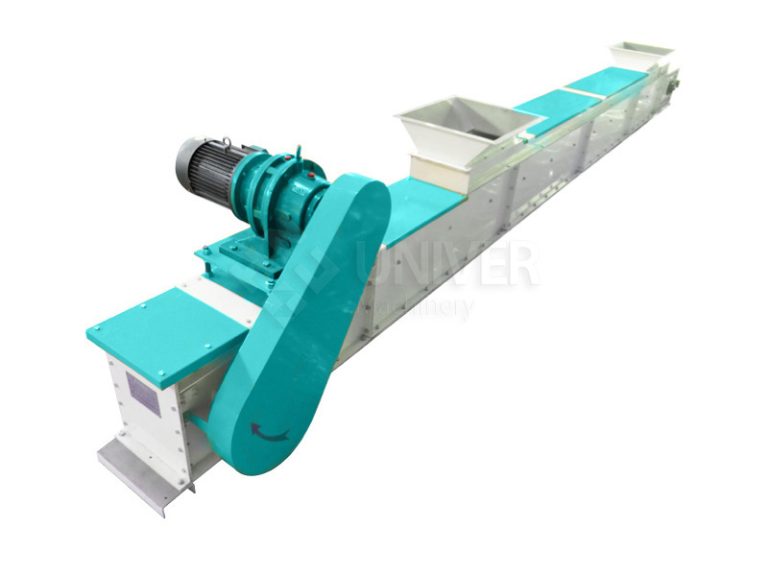

- 2. Storage and outbound section: materials will be conveyed by chain conveyor to the feed plant feed inlet directly.

- 3. Considering the raw material cleanliness, pre-cleaner machine and magnet separator are equipped to remove the impurities and iron in it, ensure good quality of final feed.

- 4. According to the material properties of soya meal, soya meal is easy to be arched when stored in the silo for a long time. The storage capacity of a single soya meal silo generally does not exceed 250T, and the single soya meal silo capacity of this project is 200T.

For different projects and different customer’s requirements, the process is different, for example:

- In this process, the unloading method is rear-side unloading, which can be designed as double-side or single-side unloading according to requirements.

- The single silo capacity of the soya meal can be selected according to the customer’s needs (single silo capacity is no higher than 250T).

Bolted silo is more and more popular in feed industry instead of big warehouse to storage the materials for feed processing. To get customized silo system solution, please send your inquiry.