- Project: bagasse pellet production line/biomass pellet plant

- Project location: Kenya

- Capacity: 4-5tons per hour.

- Raw materials: bagasse, by-product of self-owned sugar factory, it can supply up to 300tons of bagasse per day.

- Raw material moisture: 45-53%, need drying.

- Final feed size specification:

- Median diameter 9.7mm, length 22.7mm, bulk density 726.32kgm³,mechanical durability 98.2%, moisture 5.49%, heating value 16.0MJkg-1, ash content 8.7%, fixed carbon 14.03%, volatile matter 77.27%, nitrogen 0.28%, sulphur 0.02%, and chlorine <0.02%。

- End use of pellets: to supply tea manufactures as fuel.

- Pellet packing: 1 ton per bag.

Process introduction of this project:

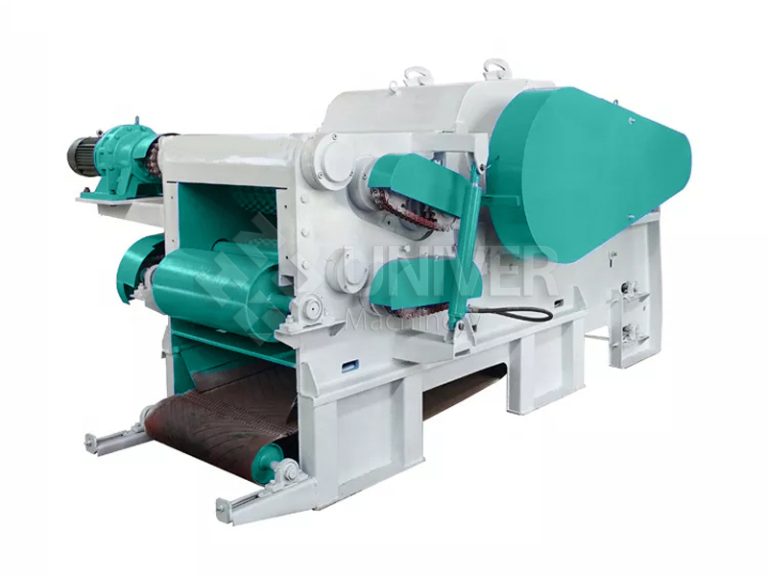

Sieving & crushing system ----drying system—pelleting & cooling system—packing system.

Main machine of complete plant: belt conveyor, vibrating screen, hammer mill, cyclone with air lock, buffer bin, drum dryer, pre-pelleting buffer bin, ring die pellet mill, cooler, vibrating screen, packing machine.

On the one hand, this production line makes full use of the by-products of the sugar factory, and on the other hand, it provides tea manufacturers with cost-effective new fuels. This method provides additional value for growers and processing, it is a win-win investment.